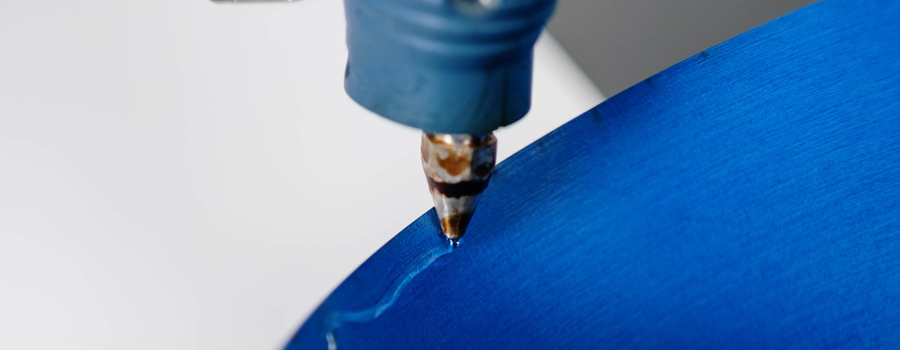

adhesives are organic or inorganic, natural or synthetic substances of the same or two or more homogeneous or heterogeneous parts (or materials) that can be joined together and have sufficient strength after curing, also known as adhesives, binders, customarily referred to as glue.

commonly used adhesives are synthetic adhesives. synthetic adhesives are composed of main agent and auxiliaries, also known as the main material, base material or adhesive; auxiliaries are curing agents, diluents, plasticizers, fillers, coupling agents, initiators, thickeners, antioxidants, inhibitors, stabilizers, complexing agents, emulsifiers, etc., according to the requirements and uses can also include flame retardants, foaming agents, defoamers, colouring agents and mould inhibitors and other components.

according to incomplete statistics, more than 6000 kinds of adhesive products have been introduced so far, because it can realize the connection of the same or different materials, no stress concentration in the joint part, high bonding strength, easy to realize the automation of chemical operation, etc., widely used in various fields in the national economy. at present, the production and sales scale of the adhesive industry continues to grow rapidly, the technical level of adhesives continues to improve, a large number of domestic and foreign advanced level products continue to emerge, adhesives to modified, reactive, multi-functional, nano-type and other directions of development, application areas also to new energy, energy saving and environmental protection and other emerging industries focus.

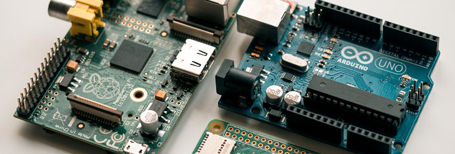

noa has nearly 30,000 square meters of central laboratory, with organic laboratory, inorganic laboratory, physical and chemical laboratory, thermal analysis laboratory, mechanics laboratory, reliability laboratory, combustion laboratory, weather resistance laboratory. it can provide one-stop analysis and testing services for adhesive products such as raw material quality control, composition analysis, foreign substance analysis, performance testing, environmental performance and reliability testing.

noa can provide composition analysis, formulation analysis, failure analysis, comparative analysis, foreign matter analysis, environmental protection testing and other services through spectroscopy, chromatography, nuclear magnetism and other large precision instruments, using "light, colour, heat, mass, meta-chemical" multi-analysis techniques, to help customers analyse the chemical composition and composition content of samples, or qualitative and quantitative analysis of specified ingredients and content according to customer requirements, identification of raw materials, additives, specific ingredients, content and foreign matter components and other analytical services.

i. service offerings

|

service offerings |

common products |

|

acrylate adhesives |

502 adhesive, anaerobic adhesive, ab adhesive, emulsion-type pressure-sensitive adhesive |

|

polyurethane adhesives |

sealants, foam adhesives |

|

epoxy resin adhesives |

electronic adhesives, sealants, sealants, anti-corrosion adhesives, structural adhesives, anchoring agents |

|

uv adhesives |

uv nail glue, uv easy peel glue, uv glass glue |

二、服务项目

|

服务名称 |

服务定义 |

|

成分分析 |

组成成分定性定量分析 |

|

体系鉴定 |

树脂体系鉴定 |

|

对比分析 |

组成成分定性定量分析 成分差异说明 性能改进建议 |

|

异物分析 |

异物发现 分析方案 测试结果 异物成分分析结论 |

|

失效分析 |

(断裂、龟裂、析出、脱层)等失效背景调查问卷 分析方案 测试结果 失效分析结论 |

|

环保测试 |

挥发性有机化合物、有害物质限量 |

|

指定成分分析 |

化合物名称及含量 测试方法 |

|

树脂结构解析 |

树脂合成单体种类及比例 |

|

大型仪器测试 |

py-gcms、tga、dsc、nmr等谱图测试 |

|

原材料质控 |

原料纯度测试、物料定性分析、指定成分定性定量分析 |

tel: 86-400 821 5138

fax: 86-21 3327 5843

email:noa@noagroup.com