in aql standards, the acceptance criteria are set based on the level of risk or quality required for a particular product or industry. minor defects are tolerated to some extent, major defects require stricter control, and critical defects are almost never allowed, as they can lead to severe consequences, including harm to consumers or significant financial liabilities for the manufacturer. the aql level chosen depends on the product's intended use and the industry standards and regulations.

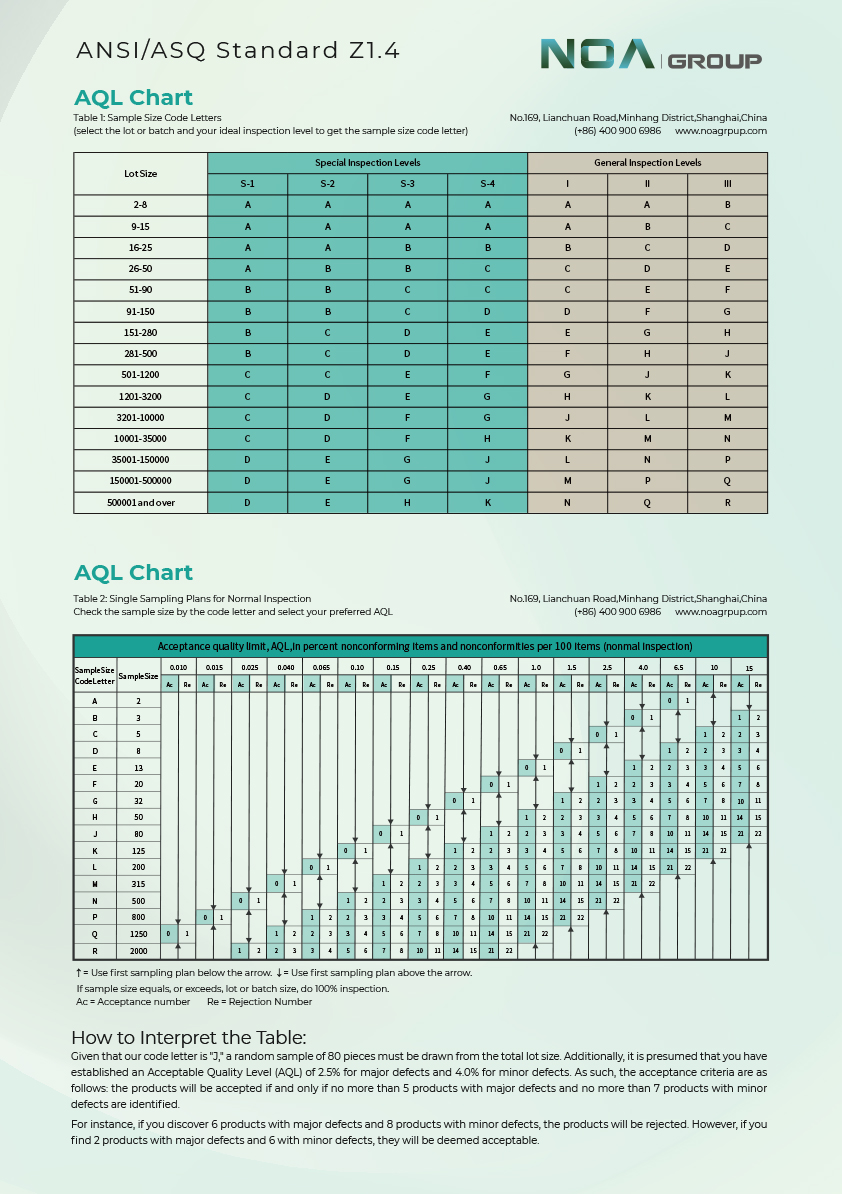

below you will find the aql table as reference.

minor defect:

- a small scratch on the surface of a product that doesn't affect its functionality.

- slight discoloration on a non-visible part of an item.

- minor deviations in product dimensions within acceptable tolerances.

example: in a batch of mobile phone cases with an aql of 2.5, a few cases may have barely noticeable scratches on the back that don't impact their protective function.

major defect:

-a manufacturing defect that affects the core functionality of a product.

-a missing or malfunctioning component that makes the product unusable.

-severe cosmetic defects on visible parts of the product.

-significant deviations from specified product specifications.

example: in a shipment of electronic tablets with an aql of 1.0, tablets that do not power on or have cracked screens would be considered major defects.

critical defect:

critical defect

-safety-related issues that pose a significant risk to consumers

-regulatory compliance violations that could lead to product recalls or legal actions.

-hazardous materials exceeding allowable limits.

-any defect that could result in harm or serious consequences.

example: in a batch of children's toys with an aql of 0.1, the presence of small parts that pose a choking hazard to children would be considered a critical defect.

tel: 86-400 821 5138

fax: 86-21 3327 5843

email:noa@noagroup.com